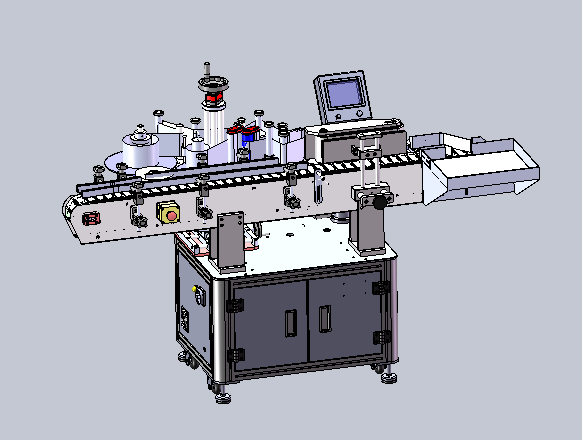

- Automatic Wrap Around Sticker Labeling Machine

- Semi Wrap Around Sticker Labeling Machine

Optional Features

Label Roll Empty Alarm

When the label rolls empty, Machine stops with the alarm

When the label rolls empty, Machine stops with the alarm

When the label rolls empty, Machine stops with the alarm

When the label rolls empty, Machine stops with the alarm

Label Roll Empty Alarm

When the label rolls empty, Machine stops with the alarm

Label Roll Empty Alarm

Salient Features

No Bottle No Label No Bottle No Label |

Total GMP Model Total GMP Model |

Strurdy Stainless Steel Frame Structure & Door Strurdy Stainless Steel Frame Structure & Door |

Advance PLC Controlled Stepper / Servo Motor Label Dispenser Unit Advance PLC Controlled Stepper / Servo Motor Label Dispenser Unit |

Vibration Free Slat Chain Conveyor With Variable Speed Drive Vibration Free Slat Chain Conveyor With Variable Speed Drive |

Touch Screen display(HMI) Touch Screen display(HMI) |

Sponge Belt For safely Label Pressing Sponge Belt For safely Label Pressing |

Bottle Separator With Variable Speed DC Drive Bottle Separator With Variable Speed DC Drive |

Fully Synchronized – Label Dispenser, Conveyor & wraparound Pressing Belt System Fully Synchronized – Label Dispenser, Conveyor & wraparound Pressing Belt System |

Very Smooth & Accurate Label Placement Very Smooth & Accurate Label Placement |

Built In Product Counter Built In Product Counter |

On-Line Speed Can Be Vary at Single touch Point On-Line Speed Can Be Vary at Single touch Point |

Partial Machine Guarding Partial Machine Guarding |

Built In Control Panel Built In Control Panel |

Auto Label Length Measurement Auto Label Length Measurement |

Height Adjustable Legs Height Adjustable Legs |

Salient Features

By Packaging Type

By Packaging Type By Industries

By Industries By Application

By Application

PET Bottle

Hdpebottle

HDPE Bottle

Aluminium Can

JAR Bottle

Tin

PET Bottle

-

By Packaging Type

By Packaging Type

-

By Industries

By Industries

-

By Application

By Application

Tin_1

Tin

Tin_1

Tin

Tin_1

Tin

Tin_1

Tin

Tin_1

Tin

Tin_1

Tin

Main Electrical Configuration

| Part Name | Make | Description |

|---|---|---|

| PLC Control system | Panasonic | High Speed PLC |

| Touch-screen | Pansonic | 3.5 ” Tocuh Screen HMI |

| Label Dispenser Motor | ImportedPanasonic | High Torque Stepper Motor Servo Motor |

| Wrapround Belt Motor | Oriental Motor | Compact AC Gear Motor |

| Photoelectric sensor (Check object) |

Wanglore / Leuze | Diffuse type Sensor |

| Label sensor (Check opaque label) | Leuze | Fork Type Label Scanner |

| Label sensor – For Trnasperent Label (Check transparent and opaque label) |

Leuze | Fork Type Label Scanner |

| Conveyor Motor | Born Vario | Induction Gear Motor |

| Speed Controller Drive | Schneider / Danfoss | Variable Frequency Drive |

| Bottle Space Creator Motor | Imported | 120 W DC Motor with Controller |

Machine Parts

2D Design

Labeling Process

01

Start Process

Feed bottles on conveyor or using automatic botte turntable. The Space Creator creates a proper gap between two containers, when the container moves on the Conveyor.

02

Control Process

Product sensor checks the presence of bottle at labeling station and when the bottle is present below the labeling station the PLC gives command to Label Dispenser to dispense the label, meanwhile The Pressing belt presses the container at appropriate pressure and the label is stuck accurately on the container.

03

Label Process

The Pressing belt presses the container at appropriate pressure and the label is stuck accurately on the container. The machine is able to label up to 100 / 200 containers per minute depending on products and label size.

Start Process

Feed bottles on a conveyor or use an automatic botte turntable. The Space Creator creates a proper gap between two containers when the container moves on the Conveyor.

Control Process

Product sensor checks the presence of bottle at labeling station and when the bottle is present below the labeling station the PLC gives command to Label Dispenser to dispense the label, meanwhile The Pressing belt presses the container at appropriate pressure and the label is stuck accurately on the container.

Label Process

The Pressing belt presses the container at appropriate pressure and the label is stuck accurately on the container. The machine is able to label up to 100 / 200 containers per minute depending on products and label size.

End Process

Then the bottle goes to the next processing.

Labeling Process

Start Process 01

Feed bottles on conveyor or using automatic botte turntable. The Space Creator creates a proper gap between two containers, when the container moves on the Conveyor.

Control Process 02

Product sensor checks the presence of bottle at labeling station and when the bottle is present below the labeling station the PLC gives command to Label Dispenser to dispense the label, meanwhile The Pressing belt presses the container at appropriate pressure and the label is stuck accurately on the container.

Label Process 03

The Pressing belt presses the container at appropriate pressure and the label is stuck accurately on the container. The machine is able to label up to 100 / 200 containers per minute depending on products and label size.

End Process 04

Then the bottle goes to the next processing.

Start Process

Feed bottles on conveyor or using automatic botte turntable. The Space Creator creates a proper gap between two containers, when the container moves on the Conveyor.

Control Process

Feed bottles on conveyor or using automatic botte turntable. The Space Creator creates a proper gap between two containers, when the container moves on the Conveyor.

Label Process

Feed bottles on conveyor or using automatic botte turntable. The Space Creator creates a proper gap between two containers, when the container moves on the Conveyor.

Start Process

Feed bottles on conveyor or using automatic botte turntable. The Space Creator creates a proper gap between two containers, when the container moves on the Conveyor.

Star Process

Ever undertakes laborious physical exercise, except too obtains some advantage from it right.

Control Process

Indignation and dislike men who are so beguileds and demoralized by the of pleasure of the moment.

Label Process

Ever undertakes laborious physical exercise, except too obtains some advantage from it right.

End Process

Indignation and dislike men who are so beguileds and demoralized by the of pleasure of the moment.

Start Process

Ever underta laborious physical exercise, excepts obtains some advantage from it right.

Control Process

Ever underta laborious physical exercise, excepts obtains some advantage from it right.

Label Process

Ever underta laborious physical exercise, excepts obtains some advantage from it right.

End Process

Ever underta laborious physical exercise, excepts obtains some advantage from it right.

FAQS

FAQS

Reviews

85

Millions of Customers

Like Our Services